| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : oem

Model Number : Customized

Certification : ISO9001, , CE, UL, TUV

Place of Origin : China

MOQ : 1 pieces

Price : negotiable

Payment Terms : L/C, T/T, Western Union, MoneyGram, D/P, D/A

Supply Ability : 5000 pieces month

Delivery Time : 15-20 working days after the order confirmed

Packaging Details : In accordance with international export standards,with moisture-proof wooden cases loading and transportation,place the bubble inside to prevent products

Feature : very thin thickness

MOQ : 1PCS

OEM : yes and welcome

Usage : Wear-resisting Material

Shipping : HL EMS UPS FEDEX TNT

Max. Working Temperature : 1500 - 1800 °C

Electrical Insulation : Excellent

Corrosion Resistance : High

Moh's Hardness : 9

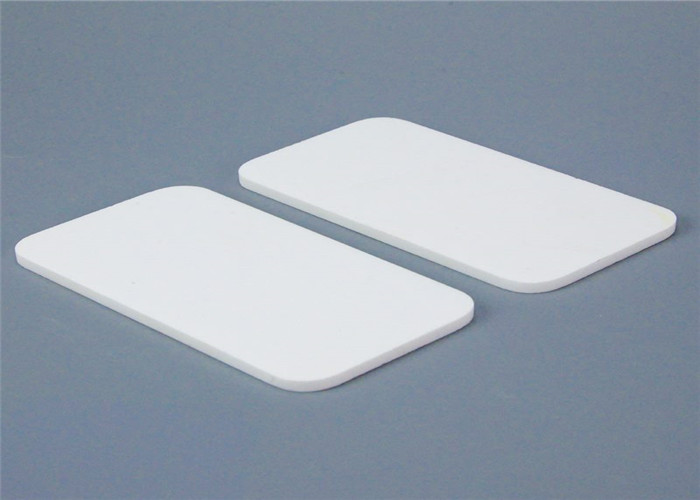

95%-99.99% alumina ceramic high temperature resistance customized large diameter plate

Specifications for Alumina sheet & Alumina plate

| Item Name | Alumina Sheet / Alumina plate |

| Material | Alumina/zirconia ceramic |

| Size | 0.3mm-50mm T x 2 - 350 mm W x 2-350 mm L |

| application | water treatment machinery system |

| Surface | with good roughness , flatness , 0% water absorbtion |

Specification

1. Refractory

2. Long service life

3. High Polished Surface

4. Superior Mechanical Strength

5. Anti-high Corrosion and Wear Resistance

6. Good Insulation Performance

7. High Temperature and Pressure Resistance

8. High Purity Zirconia and Alumina Ceramic Materials

9. High hardness, long service life, not easy to break and wear resistance

10.Non-conductive, anti-static, ceramic material itself with the insulation of electricity and magnetism properties

11.Corrosion resistance, high temperature resistance, can be applied to a specific environment, such as acid alkali resistance

| Properties | Unit | Steatite ceramic | 95% Al2O3 | 99% Al2O3 | Zirconia Ceramic |

| density | g/cm³ | 2.7 | 3.6 | 3.8 | 5.6 |

| Flexural strength | Mpa | 145 | 300 | 300 | 354 |

| Hardness | Gpa | 5.7 | 7 | 10.7 | 12.3 |

| Elastic modulus | Gpa | 120 | 275 | 320 | 205 |

| Poissons ratio | - | 0.21 | 0.22 | 0.22 | 0.30 |

| Linear expansion coefficient | x 10-6/ºC | 7.9 | 7.1 | 7.8 | 9 |

| Thermal conductivity | w/(m.k) | 2.5 | 20 | 25 | 2.5 |

| Specific Heat | *10-3J/(kg*K) | 0.75 | 0.78 | 0.78 | 0.4 |

Applications of alumina substrates:

•Alumina substrates plates are hard enough to become armor for personnel or vehicles.

• The corrosion resistivity of alumina plates makes them a great material for chemical industry.

• Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures.

• Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

• In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles and insulators.

*This chart just demonstrates the typical properties of common alumina materials we use to produce our alumina parts. Please notice that the property for customized alumina parts could vary due to different process. Stanford Advanced Materials could provide alumina products produced under your specified instruction, or do the best to meet customers’ requirements.

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high precision zirconia and alumina ceramic parts . Our main products include ceramic rod , ceramic tube, ceramic plunger, ceramic valve, ceramic plate, ceramic shaft and bearing , ceramic nozzle etc , which are mainly used in industrial fields of Machinery, Petrochemical oil and gas, Valves, Automotive, Food Processing, Fluid Handling, Process Control, Thermal Processing, Aerospace, Defense, Eletronic and Electrical, Textile, Mechanical, Engineering, Mineral Processing, etc.

We have a full service include mold design and development , ceramic forming , precision machining

and precision detection technology. We have achieved great successes in particular requirements

which is based on cooperating with Tsinghua University and getting rich experience by our professional technical engineer teams . Our factory have an unique technical called mirror polishing which improve

our products more smooth , bright than other competitors.

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die casting , tape casting , injection molding, etc, injection molding and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but paypal and western union only for small -sum payment.

|

|

High Hardness 95% - 99.7% Alumina Ceramic Plate Customized White Images |